Accident pyramid: The important message of near misses

From dangerous situations to near misses to the worst case scenario – an accident at work: With the help of the so-called accident pyramid , all incidents in the company can be analyzed. You can find out exactly what this means and what examples of the accident pyramid there are in our article. You can also read why a near miss is an important warning sign and how you can effectively avoid accidents at work with the right error culture.

Do you want to use digital solutions for accident reporting? Then take a look at our comprehensive e-book . Here we have summarized everything you need to know about digital HSQE management.

The big book of digital HSQE management

Find out in detail how a comprehensive software solution can support you in the area of HSQE!

What does the accident pyramid say?

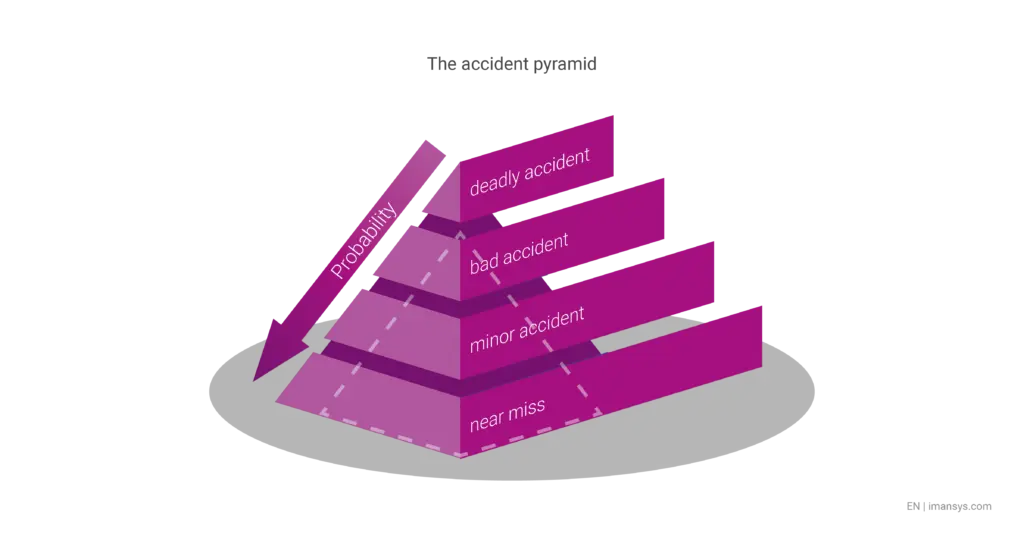

The accident pyramid model is often used when analyzing work accidents. The distribution of different accident severities is determined, which are stacked on top of each other depending on their frequency. The result is a pyramid shape . Accident researchers often speak of the “safety pyramid”. Basically, the accident pyramid can be understood as a statistical frequency distribution that shows the probability of accident levels.

You can use the accident pyramid for all types of accidents, because the model has fundamentally shown that serious or even fatal accidents are much rarer than minor accidents or unsafe behavior. While serious incidents form the top of the pyramid, so-called near misses are much more likely. What is clear is that every serious accident at work is preceded by a large number of smaller incidents . You should therefore take every near-accident in the company seriously in order to minimize higher levels of danger. The graphic below shows an exemplary accident pyramid.

The accident pyramid is usually divided into four levels :

- Near miss: risky behavior without serious consequences

- minor accident: minor injuries, continued work possible without loss of work

- Major accident: serious injuries requiring medical attention, downtime

- fatal accident: injuries resulting in death

Are near misses reportable?

Imagine the following situation: An oil stain has formed in the hallway of your company. An employee slips as a result, but is able to catch himself at the last moment. Good luck for your employee and a warning sign for you: you should take appropriate action as quickly as possible before the next employee is seriously injured in a fall. As the name suggests, an accident almost occurred.

A near miss is the result of unsafe events at work that do not, however, have serious consequences . There will be no personal injury or property damage. You can therefore understand near misses as harbingers of accidents, which at the same time show you the current level of safety in your company. By the way: If you are confused about the term “Near Misses “stumble” – this also refers to near misses.

You do not have to report near misses to your accident insurer. We still recommend that you report any near-miss incident internally – after all, it could just as easily have resulted in an accident. As a rule of thumb, if the incident could have ended up as a reportable accident, it should be recorded. You can read more about reporting work accidents in our article on the digital first aid book.

Your employees should ideally be able to report unsafe incidents to a central location . However, it is not enough to just point out the near miss. The subsequent evaluation and derivation of necessary security measures is also crucial. After all, analyzing near-miss events is about how you can prevent accidents in the future.

Accident analysis is important!

Even if there is a near-miss , you should always carry out an accident analysis. The reason for this is that the only difference between an accident at work and a near-miss is coincidence . The near-miss could just as easily have resulted in damage. In any case, it is an indication of a source of error in everyday work that you should definitely investigate. The accident analysis in the event of an accident at work therefore has several goals (excerpt):

- They clarify the exact circumstances of the accident.

- They determine the underlying chain of causes.

- They identify the technical, organizational or behavioral causes of accidents.

- They identify security measures to prevent further incidents.

- You collect information for your accident statistics.

- You prevent future accidents and thus increase safety in your company.

Overview of various accident pyramids

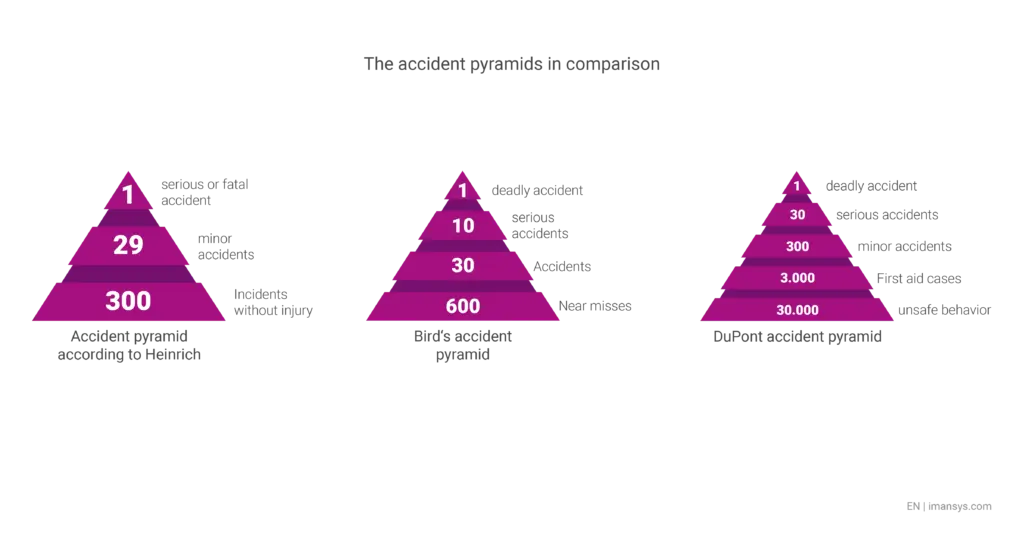

Below we present three common accident pyramids and show you the main differences.

Accident pyramid according to Heinrich

The pioneer of the classic accident pyramid was Herbert William Heinrich. In 1931, he investigated the influence of a company’s safety culture on the number of accidents. Based on the results of several thousand accidents at work, he determined a pyramid that was composed of the accident distribution. The safety pyramid, known as “Heinrich’s Triangle”, resulted in a distribution of 300 incidents – i.e. accidents without injuries – and 29 minor accidents with only one fatal or serious accident at work. Therefore, it is often referred to today as ” Heinrich’s Triangle 300-29-1” .

Heinrich finally realized that any reduction in the pyramid base automatically has a positive effect on the occurrence of serious accidents. Preventing minor injuries should therefore prevent serious incidents. What was not taken into account in Heinrich’s accident model, however, were organizational and psychological aspects of work processes. These are, however, crucial for solving work accidents.

Bird’s accident pyramid

Occupational safety expert Frank E. Bird also analyzed more than 1.7 million accidents in 1996. Like Heinrich, he recognized that serious accidents occur relatively rarely. The classification of his accident pyramid was more precise: he divided into fatal accidents and serious accidents with loss of working time, minor accidents and near misses. Bird’s research found a 1-10-30-600 ratio . This means: For every fatal accident, there are ten serious accidents, 30 accidents that require medical intervention and 600 near misses.

DuPont accident pyramid

The DuPont accident pyramid is somewhat less well known. As a model with the most levels, first aid cases are also included here. Near misses also belong to the expanded category of unsafe behavior. However, it is not surprising that at DuPont there is also a significant connection between the number of unsafe actions and the number of minor, serious and fatal accidents.

No matter which distribution of the accident pyramid is considered, the basic message is the same for all forms: It is important for occupational safety in your company to draw conclusions from a near-accident in order to prevent more serious outcomes. The company’s error culture has a major influence on this.

Learning from near-accidents with the right reporting and error culture

Finally, we would like to introduce you to some criteria that make up a good error and reporting culture in the company. Only by involving all employees in effective reporting systems can you learn from the sources of accidents.

What a good error culture includes (excerpt):

- Employees can report errors or deficiencies in operational safety measures at any time without fear of sanctions or exposure.

- With the help of simple and time-saving reporting options, near misses can be systematically recorded by everyone.

- Sources of accidents and errors are dealt with transparently. Employees who report near-accidents are treated confidentially and anonymously.

- The aim is continuous improvement processes. In order to learn from the accident pyramid, reported safety risks are assessed and necessary measures are derived. Employees also receive feedback on reported incidents.

- The error culture is anchored in the company guidelines and is communicated to employees, for example, in regular training.

The correct culture of reporting near misses is therefore crucial. Many large companies are now using digital reporting systems . The use can also be worthwhile for small and medium-sized companies.

With our software solution iManSys, all employees can report not only accidents, but also near misses, regardless of time or location. To do this, simply provide all the details of the incident in the digital accident report . Finally, you can also derive necessary measures. It is also possible to detect dangerous situations.

It is particularly useful to instruct your employees about existing risks after a near-accident or dangerous situation occurs. Electronic safety instructions are also integrated in iManSys and can be assigned as a measure. Finally, create clear statistics on the distribution of all accidents, near-accidents and dangerous incidents and draw conclusions from this for occupational safety in your company.

how digital accident reporting with iManSys works in detail in our free e-book . Here we also inform you about other advantages of HSQE software, such as digital risk assessment to prevent incidents from occurring. We hope you enjoy reading it!

The big book of digital HSQE management

Find out in detail how a comprehensive software solution can support you in the area of HSQE!

Tags:

Share this article:

More blog posts

Creating a hazardous substances register

The Ordinance on Hazardous Substances requires every employer to keep a register of all hazardous substances existing in the company. This register provides information not only about a substance, its […]

Food safety

Food sold in the EU is subject to high quality and safety requirements. A control system that the responsible food companies set up based on the HACCP principles helps with […]

Leave a Reply