Accident analysis after a work accident

Unfortunately, accidents at work are not uncommon and can have severe consequences for those affected and their companies. Both commuting accidents and accidents on company premises are covered by accident insurance. In this article, you will learn about the legal requirements for accident analysis, the methods and tools used, and the process. Please note: All legal context in this text refers to the German law. Regulations may differ in other countries.

Would you also like to learn how to implement accident management digitally in your company? Then we recommend our comprehensive e-book!

The big book of digital HSQE management

Find out in detail how a comprehensive software solution can support you in the area of HSQE!

Importance and objectives of accident analysis

Definition and objectives of accident analysis

Accident analysis is used to systematically investigate workplace accidents. During the investigation, the causes are determined, and individual measures are developed. The aim is to prevent accidents in the future and increase workplace safety.

Legal requirements for accident analysis

Employers are obliged to investigate and document accidents to meet legal requirements. The Occupational Safety and Health Act and specific regulations of the professional associations regulate this.

An accident report must be submitted to the employers’ liability insurance association if

The professional association ensures that all necessary steps are taken to protect the insured.

Importance of accident analysis for the prevention of occupational accidents

If companies investigate an incident systematically, they can often quickly and reliably identify the possible causes. Once the cause is known, a customised solution can bedeveloped. In this way, companies continuously improve safety in the workplace and significantly reduce the risk of future accidents.

Benefits of accident analysis for companies and employees

Systematic investigations help both employers and employees. Companies increase safety in the workplace through the derived precautions. This minimises downtime, reduces legal liability risks, and promotes a positive atmosphere in the workplace. Employees see and experience the company’s goal-oriented commitment in their everyday work. This promotes a safety-conscious corporate culture and protects employees from further dangers.

Challenges in analysing an accident at work

The basic requirement for the analysis is that the entire process on the day of the accident is precisely documented with all details. A systematic evaluation of the information is crucial, and cooperation with the company doctor can help consider medical aspects. In addition, all legal reporting obligations must be met on time to ensure the accident is reported correctly to the accident insurance providers.

Process of systematic accident investigation

The systematic accident investigation includes specific steps, which we briefly introduce below.

1. Securing the accident site and collecting evidence

The accident site must be cordoned off and secured as soon as possible after the accident. All data relevant to the investigation is recorded for evidence gathering, including photos of the accident site, witness statements, objects, machines, and other evidence involved. It is also important to inform the accident insurance fund within the prescribed three-day period and to report the accident correctly to meet legal requirements.

2. Reconstruction of the accident

Interviews with witnesses and those affected help to reconstruct the exact sequence of events of the accident. Reconstruction is an essential part of the entire process. It includes examining the place, the time, the people involved, the activities carried out and the objects involved. The events are written down in the correct order and, if necessary, supported by pictures or other evidence.

3. Determination of the causes of accidents

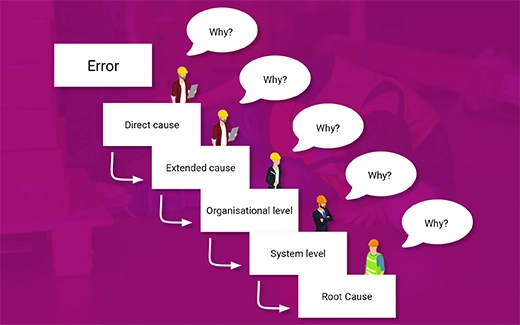

Root cause analysis identifies direct and indirect factors that led to the accident. All aspects are taken into account, including human error, technical deficiencies, and organisational weaknesses. The goal is to find the exact causes of the accident and take necessary steps to minimise the risk of a similar incident in the future.

4. Development of accident prevention measures

The investigation’s results serve as a starting point for planning and implementing preventive adjustments. These adjustments are intended to prevent similar accidents in the future. The measures include technical and organisational changes and training and instruction for employees.

5. Documentation and communication

All steps, including proper reporting, must be carefully documented, and the results must be communicated to the relevant departments inside and outside the company. Thorough and complete documentation ensures that all countermeasures developedare understandable and that future prevention strategies can be based on them. In addition, such an approach enables transparent communication of the results to all affected employees and managers at any time. Even years later, it is possible to use the documentation created to revisit the situation at the time, either to check compliance with the improvement measures once taken or to find out the original background.

Methods and tools for accident analysis

You can choose different approaches to investigate an accident. We will introduce you to the most critical methods.

5-W method (What, Where, When, Who, How)

The 5-W method is an effective tool for determining root causes. It ensures that all relevant aspects are systematically reviewed and recorded by answering the following questions:

What happened?

Where did it happen?

When did it happen?

Who was involved?

How did it happen?

This structured approach ensures that you can comprehensively record and process everything happening.

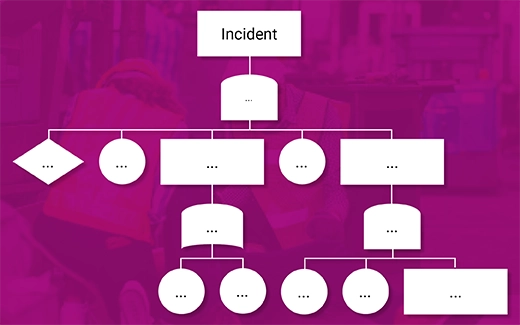

Fault tree analysis

Fault tree analysis is a visual representation of the relationships between the various causes of an accident. It starts with the accident at the top of the tree and branches into all possible fault sources and causes. Each branch represents a possible cause or condition that could have contributed to the accident.

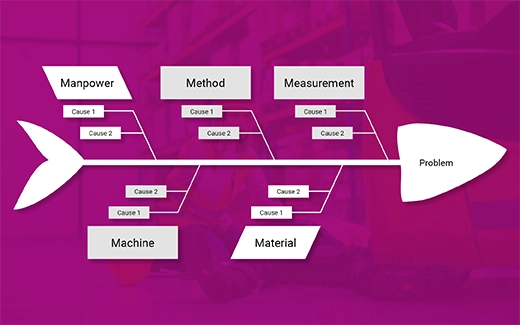

Cause-and-effect diagram

The Ishikawa diagram, also known as a cause-and-effect diagram, visualises the main causes of a problem. It consists of a central arrow representing the problem, from which several branches extend. These branches represent categories of causes such as human, machine, method, material, environment, and management. Under each category, specific causes that can influence the problem are listed.

Sequentially Timed Events Plotting (STEP)

Sequentially Timed Events Plotting (or STEP for short) investigates accidents by examining the detailed sequence of events and interactions between humans, machines, and the environment. It uses a step-by-step approach to identify sources of errors and determine causes, effects, and interactions.

Software for accident data collection and analysis

With iManSys, you have a modern software solution at your fingertips that supports you in your work related to data collection, analysis and evaluation. It also helps with the development and implementation of preventive measures.

Checklists and questionnaires

Standardised checklists and questionnaires are guidelines for systematically reviewing and recording all relevant aspects of an accident. They ensure the data is recorded comprehensively and provide the framework for further processing.

Accident analysis of work accidents – this is how to do it digitally

Digitalisation offers numerous advantages: It enables efficient data collection, rapid evaluation and accessible communication of the results to all involved. With our software solution, iManSys, you can digitally handle your company’s accident analysis process and continuously optimise your prevention strategies.

Digital processing saves time and resources and offers high accuracy and traceability. Modern technologies help us better understand accidents and minimise future risks. iManSys also makes it easier to comply with the reporting obligation on time, ensuring that all requirements are met wholly and legally.

With iManSys, you have a modern software solution at your fingertips that supports your work related to data collection, analysis, and evaluation. It also helps with the development and implementation of preventive measures. If you would like to find out more, take a look at our software world, “Risks & Hazards!”

Digital risk management

Reporting accidents at work, carrying out risk assessments and managing hazardous substances – all in one place? Find out how it works!

Tags:

Share this article:

More blog posts

Creating a hazardous substances register

The Ordinance on Hazardous Substances requires every employer to keep a register of all hazardous substances existing in the company. This register provides information not only about a substance, its […]

Food safety

Food sold in the EU is subject to high quality and safety requirements. A control system that the responsible food companies set up based on the HACCP principles helps with […]

Leave a Reply